-

Як правільна ўсталяваць ашалёўку з алюмініевых кампазітных панэляў

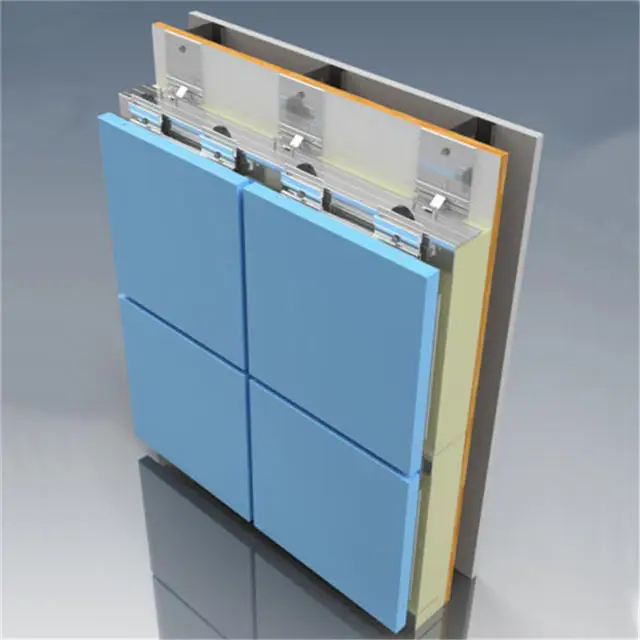

Пасля таго, як вы выразалі панэлі, прыкладзеце іх да сцяны. Альбо ён можа прыляпіцца і прыляпіцца з дапамогай клею, альбо прыкруціць панэлі да сцяны. Вы павінны пераканацца, што панэлі размешчаны роўна. Няправільная ўстаноўка можа паўплываць на знешні выгляд і функцыянаванне, калі не ўлічваць гэтыя важныя элементы. Нарэшце, калі ўсе панэлі ўстаноўлены, вы павінны зачыніць усе шчыліны па краях, каб вада не пранікала ўнутр і каб ваша ашалёўка была воданепранікальнай.

-

Розныя тыпы аздаблення для ашалёўкі з алюмініевых кампазітных панэляў

Абліцоўванне з алюмініевых кампазітных панэляў выпускаецца ў розных колерах і аздабленнях. Распаўсюджаная аздабленне - шчотка, калі матэрыял мае тэкстуру і глыбіню, якія дадаюць характару. Яшчэ адзін выбар - матавае пакрыццё, якое надае чысты і плоскі выгляд. Ён можа дадаць будынку свежасці. Лепш за ўсё аздабленне, на якое варта паглядзець, - гэта глянцавае, якое вельмі бліскучае і прыцягвае ўвагу, металік дадае унікальны бляск разам з аздабленнем, якое выглядае як дрэва, для натуральнага драўлянага пакрыцця.

-

Даўгавечнасць і нізкія эксплуатацыйныя выдаткі ашалёўкі з алюмініевых кампазітных панэляў

Ашалёўка з алюмініевых кампазітных панэляў таксама распрацавана так, што не патрабуе абслугоўвання, таму ў будучыні вам не прыйдзецца турбавацца аб частым доглядзе або рамонце. Ён неўспрымальны да суровых умоў надвор'я, уключаючы дождж, снег і моцны вецер, дзякуючы сваёй надзвычай высокай трываласці, таму можа праслужыць доўгі час, не патрабуючы асаблівага абслугоўвання. Даглядаць за матэрыялам таксама нескладана. Проста працярыце яго мяккай тканінай і невялікай колькасцю сродкі для мыцця посуду, і ўсё, што вам трэба зрабіць, гэта падтрымліваць яго ў чысціні. У выніку ўладальнікі будынкаў могуць мець ашаламляльную ашалёўку і ні ў якім разе не павінны марнаваць празмерны час і ўключаць выдаткі на яе кіраванне.