-

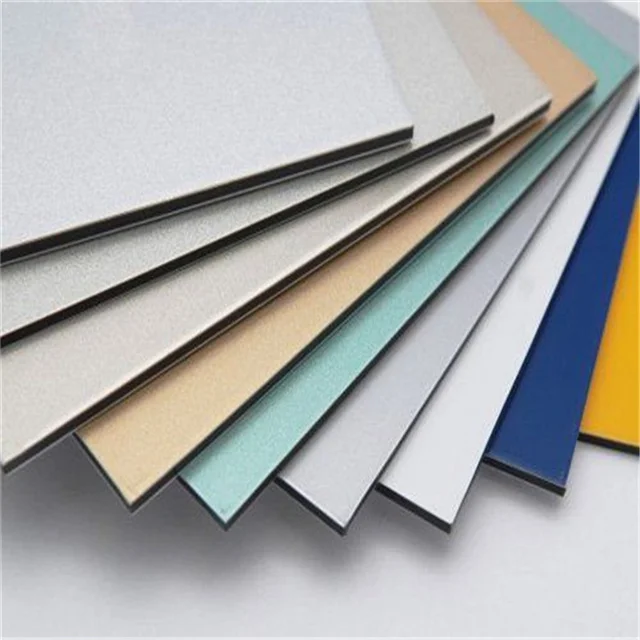

Különböző típusú alumínium kompozit panelek

Az ACM panelek két kategóriába sorolhatók; A polietilén (PE) beltéri használatra és a tűzgátló (FR) panelek alkalmasak kültéri használatra, mivel FR-védett. Az FR panelek ásványi anyagokkal töltött, alacsony éghetőségű magjuknak köszönhetően ideálisak olyan épületek esetén, ahol tűzállóságra van szükség.

-

ACM alumínium kompozit panelek lépésről lépésre szerelése modern épületek homlokzataihoz

Az ACM alumínium panel felszerelésének folyamata viszonylag egyszerűbb, feltéve, hogy betartja ezeket a létfontosságú lépéseket.

Felület előkészítése: Győződjön meg arról, hogy a felület tiszta és szennyeződésmentes, hogy javítsa a panel tapadását.

Mérés és vágás: ollóval vagy pengével mérje meg a paneleket aszerint, hogy melyikbe szeretné vágni.

Ragasztó beszerelés: Vigyen fel némi ragasztót a panel hátoldalára és a telepítési helyre.

-

Panelfektetés: A felülettel szemben a megfelelő helyzetben, hézagmentesen és megfelelően elhelyezve.

Végső részletek: Fejezd be a telepítést vágással és oldalsó darabokkal, valamint szögelj össze mindent a tiszta felület érdekében.

Környezeti hatás Számos környezetbarát lehetőséget kell mérlegelnie a kivitelezőknek, amikor fenntarthatóságuk és életciklusuk alapján modern építőanyagot választanak.

Megállapítottuk, hogy egyrészt az ACM alumínium kompozit paneleket előnyben részesítik az építőiparban, miközben a környezeti hatásukkal kapcsolatos aggodalmakra is fény derült. Ez komoly veszélyt jelent a környezetre, és minden azon múlik, hogy hogyan ártalmatlanítják megfelelően, honnan szerezzük be a nyersanyagainkat és melyek a gyártási folyamatok. A gyártók fenntartható technikákat alkalmaznak, beleértve az újrahasznosítható anyagokat a panelgyártás során

Az ACM alumínium kompozit panelek széles körű felhasználási területeinek kutatása a belsőépítészeti alkalmazásokban

Az ACM panelek nem csak kültéri használatra alkalmasak, hanem bármilyen beltéri projekthez, például falburkolatokhoz, mennyezetekhez és bútorokhoz alkalmazhatók. Az ACM panelek széles körben használhatók, és sokoldalú természetük korlátlan színválasztékot, stílust és panelkonfigurációt tesz lehetővé bármilyen tervezési ötlet kielégítésére.

Akril-sztirol gyanta az optimális szilárdság és a szélsőséges időjárásállóság érdekében; A fenti jellemzők hozzájárulnak azon előnyök listájához, amelyek miatt az ACM alumínium kompozit panelek (például az acm lite) jobb választás építészeti projektekhez, a tartósság, a rugalmas használat és a dizájn páratlan keverékével. A végrehajtási folyamatnak és a környezeti hatásnak is része kell, hogy legyen annak a döntő tényezőnek, hogy milyen típusú ACP-t (HENZ Panel) válasszunk egy projekthez. Ha szeretne belemerülni a részletekbe, és jó tanácsokat szeretne kapni egy szakértőtől, forduljon a Metal Design Teamhez.