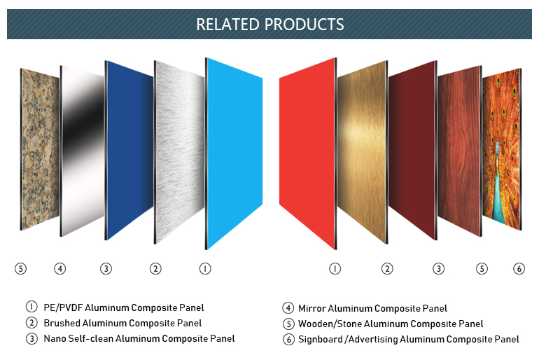

PE/PVDF Coated ACP Constitution Structure:

1) Protective film with Trubond/OEM brand or as requested.

2) Front side: aluminum roll coated with PE/PVDF

3) Macromolecular lamination film.

4) Core: Non-toxic polyethylene.

5) Macromolecular lamination film.

6) Rear side: Aluminum coated with primer or as requested.

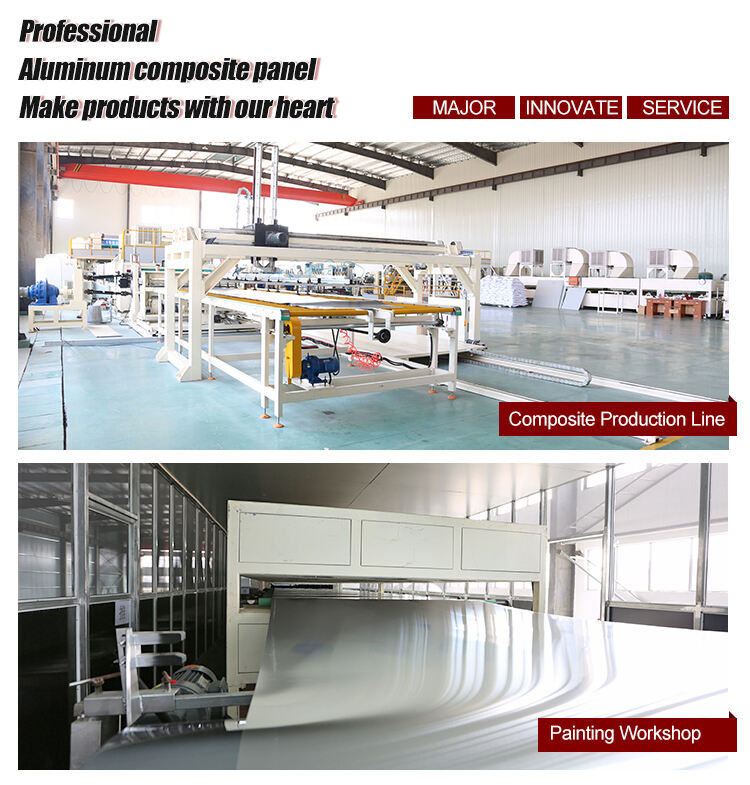

aluminum composite panel sheet manufacturers

Aluminum composite panel consisting of two aluminum cover sheets(AA1100 Series or AA3003 Series) sandwiching a non-toxic low density polyethylene core produced from a continuous extrusion process. Used for cladding, advertising. It’s usually called Aluminum composite panel, shortened as ACP or ACM.

1) Material:

A) Front: aluminum alloy sheet coated fluoro-carbon resin (PVDF) with Nano lacquer.

B) Core: nontox low density polyethylene.

C) Back: aluminum alloy sheet coated with polyester resin painting.

D) Surface coating thickness: 32μ±1μ.

E) Aluminum alloy: 3003 H24.

F) Sheet thickness: 0.3mm, 0.4mm, 0.5mm.

2) Dimensions:

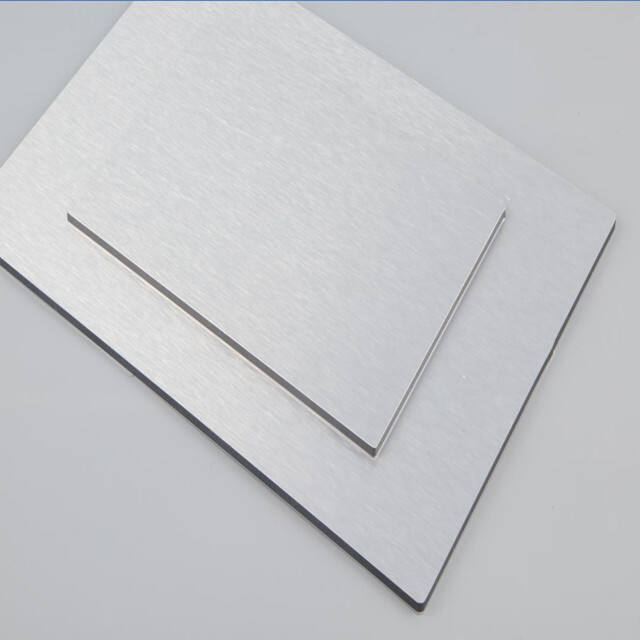

A) Thickness: 3mm,4mm,6mm,8mm,10mm.

B) Width: 1220mm,1250mm,1500mm,1570mm,1800mm,2000mm(max).

C) Length: 2440mm, 3050mm, and 3200mm (max: 6000mm).

D) Weight: 5.5kg/sqm based on 0.5/4mm thickness.

E) Standard size: 1220*2440mm.

F) Qty/20'fcl: 4mm/2380sqm; 3mm/2977sqm.

G) Non-standard size are available according to requirement.

3) Standard:

A) West Europe standard (Germany DIN Standard).

B) The EAST Europe standard (Russian standard).

C) The North America ASTM standard.

Trubond ACP | Aluminum | ||||

Rigidity (E J) | Section modulus | Thickness | Weight | Thickness | |

1250 kN cm2/m | 1.25 cm3/m | 3 mm | 4.5kg/m2 | 2.7 mm | |

2400 kN cm2/m | 1.75 cm3/m | 4mm | 5.5kg/m2 | 3.3 mm | |

Panel density | 5.5kg/m2 |

Aluminum Skin Thickness | Average 7.0 N/mm |

Tensile Strength | 52.5 Mpa |

Flexural Strength | 100.0 Mpa |

Shear Strength | 28.1 Mpa |

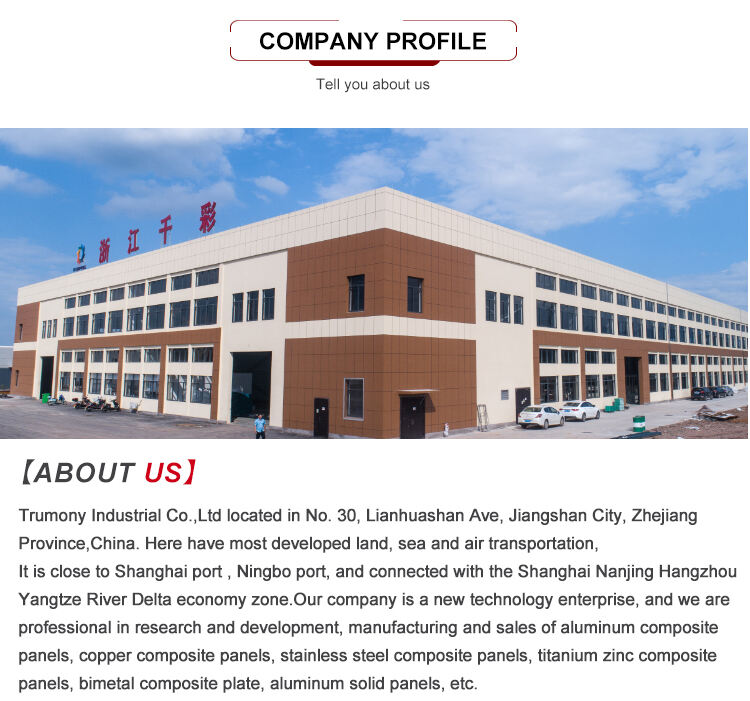

TRUBOND

If you should be hunting for a sturdy, high-quality panel for the construction or design project, TRUBOND's ACP/ACM/Alucobond/3mm 4mm Aluminum Composite Panel are exactly what you will need. This panel is durable created using an aluminum is sturdy, sandwiched between two layers of high-density polyethylene (HDPE) material. The end result is merely a solid, lightweight panel is good for the wide assortment of applications.

Versatile and may be used for pretty much every task you'll be able to imagine. It really well suited for construction jobs also it's frequently employed for façades, cladding, roofing, and design interior. The panel can be well suited also for indications, shows, and materials are point-of-sale. It might easily be cut and shaped to match any design, and yes it's very easy to put in with fundamental tools.

Durable. The panel is resistant to corrosion and weather, causing this to be suitable for use within harsh surroundings are outside. It is also incredibly strong and impact-resistant, meaning it could stay real to your tear and use of hefty after a few years. The panel normally fire-resistant, assisting to ensure it is a selection buildings which can be fantastic other structures where fire security is a problem.

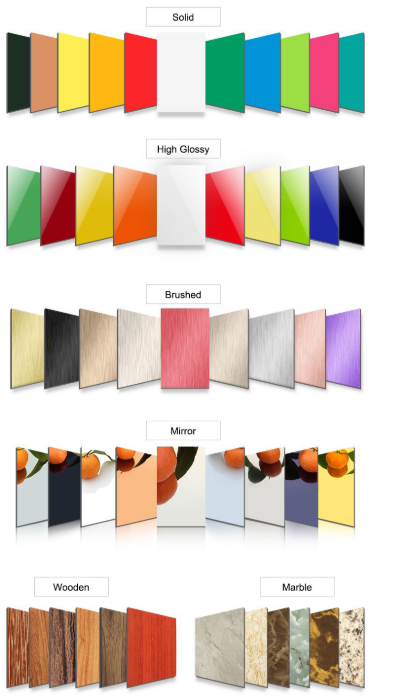

An additional benefit is its aesthetic appeal. The panel comes in a variety of colors, finishes, and textures, to help the look is got by you is perfect assembling your shed. You covered it has whether you might be interested in a classic, clean look or even a bold, modern design.

Go shopping for your TRUBOND ACP/ACM/Alucobond/3mm 4mm Aluminum Composite Panel and start producing the projects which are perfect today.

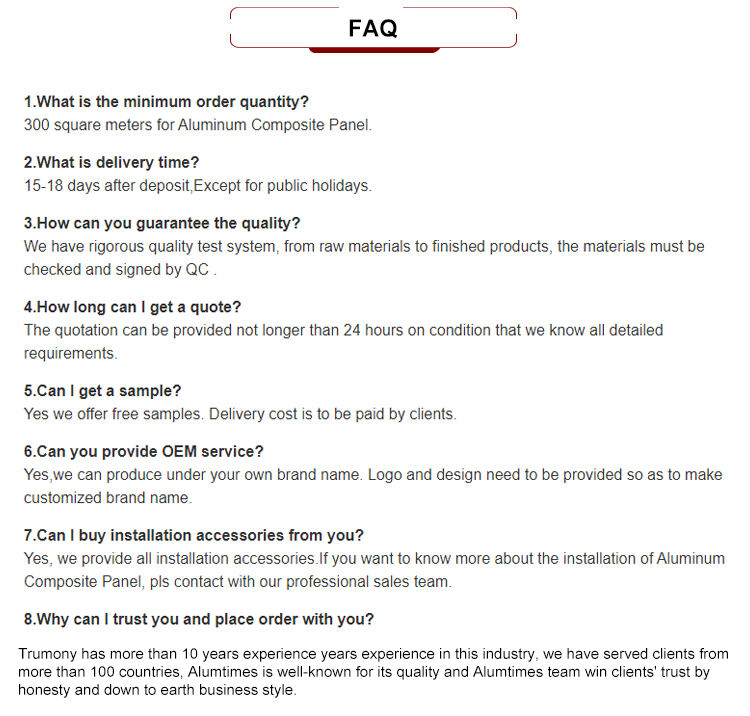

Our professional sales team are waiting for your consultation.