PE/PVDF Coated ACP Constitution Structure:

1) Protective film with Trubond/OEM brand or as requested.

2) Front side: aluminum roll coated with PE/PVDF

3) Macromolecular lamination film.

4) Core: Non-toxic polyethylene.

5) Macromolecular lamination film.

6) Rear side: Aluminum coated with primer or as requested. Aluminum composite panel sheet manufacturers

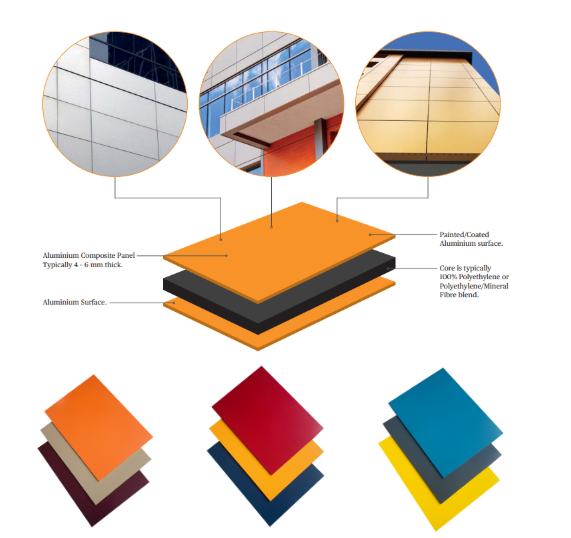

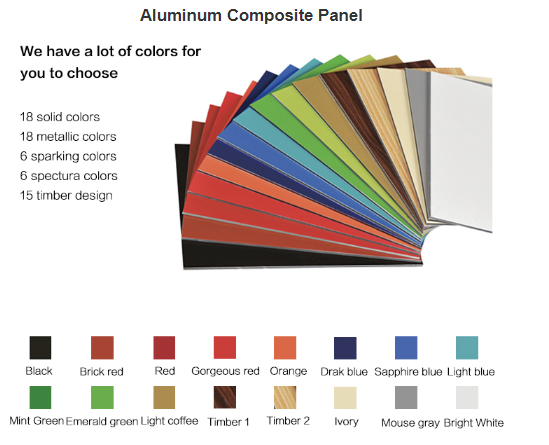

Aluminum composite panel consisting of two Aluminum cover sheets (AA1100 Series or AA3003 Series) sandwiching a non-toxic low density polyethylene core produced from a continuous extrusion process. Used for cladding, advertising. It’s usually called Aluminum composite panel, shortened as ACP or ACM.

A) Front: Aluminum alloy sheet coated fluoro-carbon resin (PVDF) with Nano lacquer.

B) Core: nontox low density polyethylene.

C) Back: Aluminum alloy sheet coated with polyester resin painting.

D) Surface coating thickness: 32μ±1μ.

E) Aluminum alloy: 3003 H24.

F) Sheet thickness: 0.3mm,0.4mm,0.5mm.

2)Dimensions:

A) Thickness: 3mm,4mm,6mm,8mm,10mm.

B) Width: 1220mm,1250mm,1500mm,1570mm,1800mm,2000mm(max).

C) Length: 2440mm,3050mm,3200mm (max:6000mm).

D) Weight: 5.5kg/sqm based on 0.5/4mm thickness.

E) Standard size:1220*2440mm.

F) Qty/20'fcl:4mm/2380sqm; 3mm/2977sqm.

G) Non-standard size are available according to requirement.

3)Standard:

A) West Europe standard (Germany DIN Standard).

B) The EAST Europe standard (Russian standard ).

C) The North America ASTM standard.

ACP compared with different products (Lightness / Rigidity):

The composite structure of Trubond results in an impressive strength-to-weight ratio, even when comparing large panel sizes.

Despite its low weight, which makes Trubond easy to transport and handle in the factory and on site, its rigidity and high

strength make the panels keep their shape and remain flat, even when exposed to extreme temperature changes. Comparison of

thickness and weight of panels with equal rigidity.

Trubond ACP compared with solid Aluminum:

Required thickness and actual weights of panels with same rigidity

Trubond ACP | Aluminum | ||||||

Rigidity (E J) | Section modulus | Thickness | Weight | Thickness | |||

1250 kN cm2/m | 1.25 cm3/m | 3 mm | 4.5kg/m2 | 2.7 mm | |||

2400 kN cm2/m | 1.75 cm3/m | 4mm | 5.5kg/m2 | 3.3 mm | |||

Panel density | 5.5kg/m2 |

Aluminium Skin Thickness | Average 7.0 N/mm |

Tensile Strength | 52.5 Mpa |

Flexural Strength | 100.0 Mpa |

Shear Strength | 28.1 Mpa |

TRUBOND

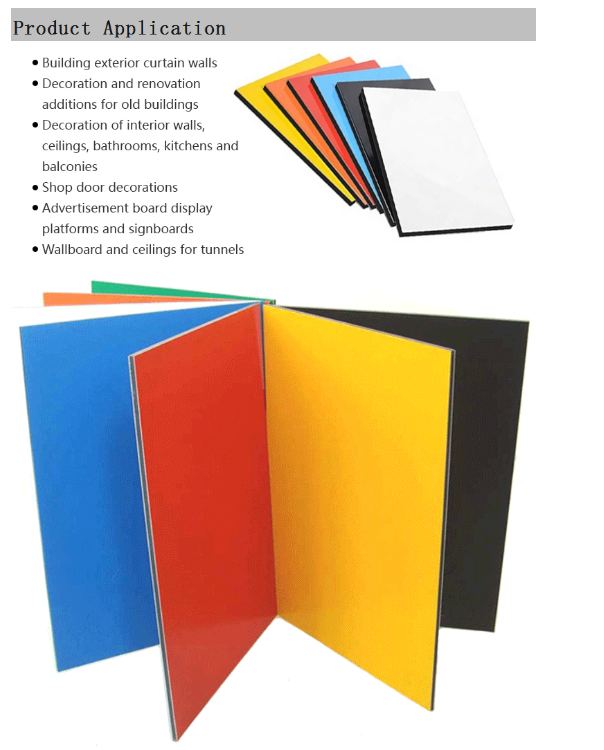

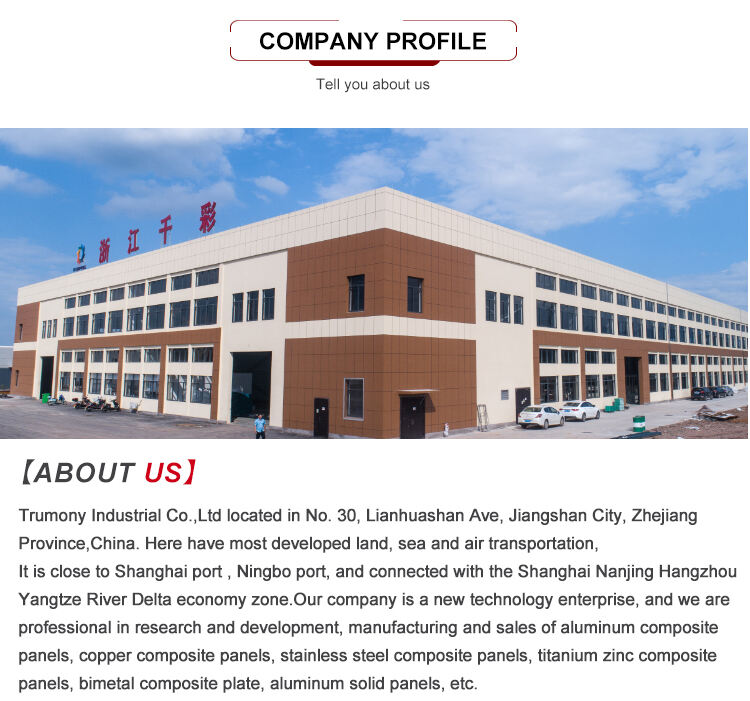

Looking for high-quality aluminums composite panels for your construction or design projects? Look no further than Factory Price ACM ACP Sheet Aluminum Composite Panels.

Made from sturdy, durable materials, these aluminums composite panels would be the choices is perfect those seeking an affordable solution it doesn't sacrifice on quality. Available TRUBOND in both 3mm and 4mm thicknesses, these panels are designed to delivers power is superior stability, ensuring that your tasks stand the test of the time.

Very easy to installs, making it an excellent option for both amateur and professional builders alike along with its lightweight designs. Whether you're constructing a building is new renovating an existing one, these panels provide the perfect finishing touch, with their sleek, modern looks adding a feeling of beauty to any structures.

What's more, these panels are available at a factory is competitive, making them a great choice for budget-conscious builders that don't want to sacrifice on quality. Ideal choice for anyone seeking an affordable and reliable building solution with its durable construction and long-lasting finish.

So why wait? Order your TRUBOND Factory Price ACM ACP Sheet Aluminum Composite Panels today and start building the project of your dreams. with their superior construction and unbeatable price, you won't find a better option for your construction needs.

Our professional sales team are waiting for your consultation.