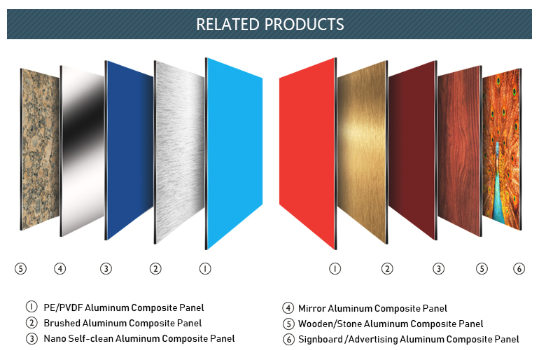

PE/PVDF Coated ACP Constitution Structure:

1) Protective film with Trubond/OEM brand or as requested.

2) Front side: aluminum roll coated with PE/PVDF

3) Macromolecular lamination film.

4) Core: Non-toxic polyethylene.

5) Macromolecular lamination film.

6) Rear side: Aluminum coated with primer or as requested.

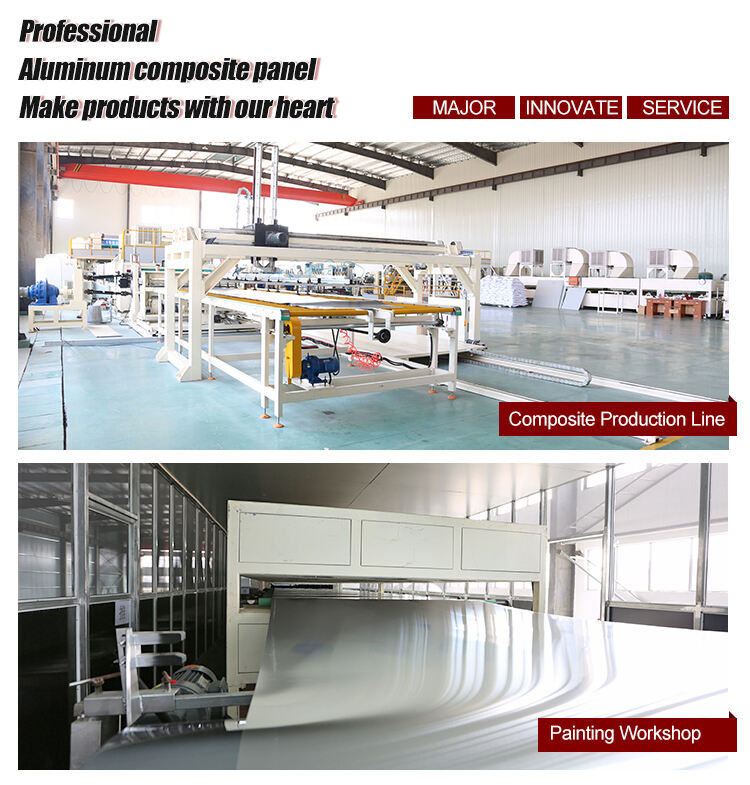

aluminum composite panel sheet manufacturers

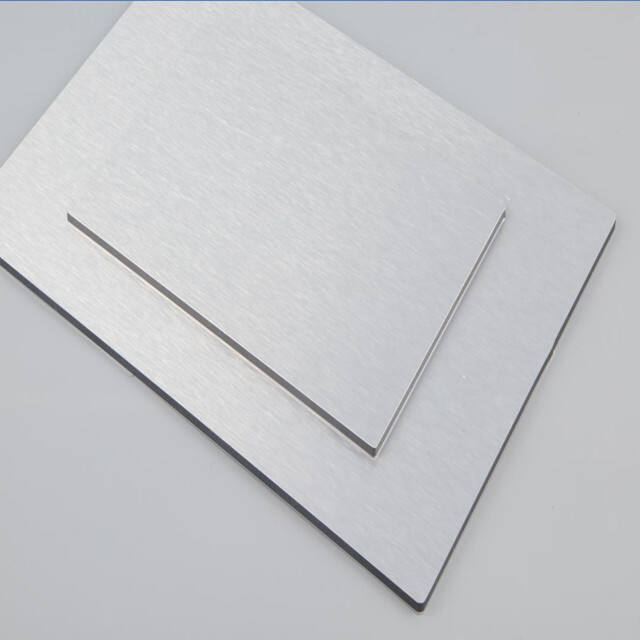

Aluminum composite panel consisting of two aluminum cover sheets(AA1100 Series or AA3003 Series) sandwiching a non-toxic low density polyethylene core produced from a continuous extrusion process. Used for cladding, advertising. It’s usually called Aluminum composite panel, shortened as ACP or ACM.

Product Description

1) Material:

A) Front: aluminum alloy sheet coated fluoro-carbon resin (PVDF) with Nano lacquer.

B) Core: nontox low density polyethylene.

C) Back: aluminum alloy sheet coated with polyester resin painting.

D) Surface coating thickness: 32μ±1μ.

E) Aluminum alloy: 3003 H24.

F) Sheet thickness: 0.3mm, 0.4mm, 0.5mm.

2) Dimensions:

A) Thickness: 3mm,4mm,6mm,8mm,10mm.

B) Width: 1220mm,1250mm,1500mm,1570mm,1800mm,2000mm(max).

C) Length: 2440mm, 3050mm, and 3200mm (max: 6000mm).

D) Weight: 5.5kg/sqm based on 0.5/4mm thickness.

E) Standard size: 1220*2440mm.

F) Qty/20'fcl: 4mm/2380sqm; 3mm/2977sqm.

G) Non-standard size are available according to requirement.

3) Standard:

A) West Europe standard (Germany DIN Standard).

B) The EAST Europe standard (Russian standard).

C) The North America ASTM standard.

ACP compared with different products (Lightness / Rigidity):

The composite structure of Trubond results in an impressive strength-to-weight ratio, even when comparing large panel sizes.

Despite its low weight, which makes Trubond easy to transport and handle in the factory and on site, its rigidity and high

strength make the panels keep their shape and remain flat, even when exposed to extreme temperature changes. Comparison of

thickness and weight of panels with equal rigidity.

Trubond ACP compared with solid aluminum:

Required thickness and actual weights of panels with same rigidity

Trubond ACP | Aluminum | ||||||

Rigidity (E J) | Section modulus | Thickness | Weight | Thickness | |||

1250 kN cm2/m | 1.25 cm3/m | 3 mm | 4.5kg/m2 | 2.7 mm | |||

2400 kN cm2/m | 1.75 cm3/m | 4mm | 5.5kg/m2 | 3.3 mm | |||

Panel density | 5.5kg/m2 |

Aluminium Skin Thickness | Average 7.0 N/mm |

Tensile Strength | 52.5 Mpa |

Flexural Strength | 100.0 Mpa |

Shear Strength | 28.1 Mpa |

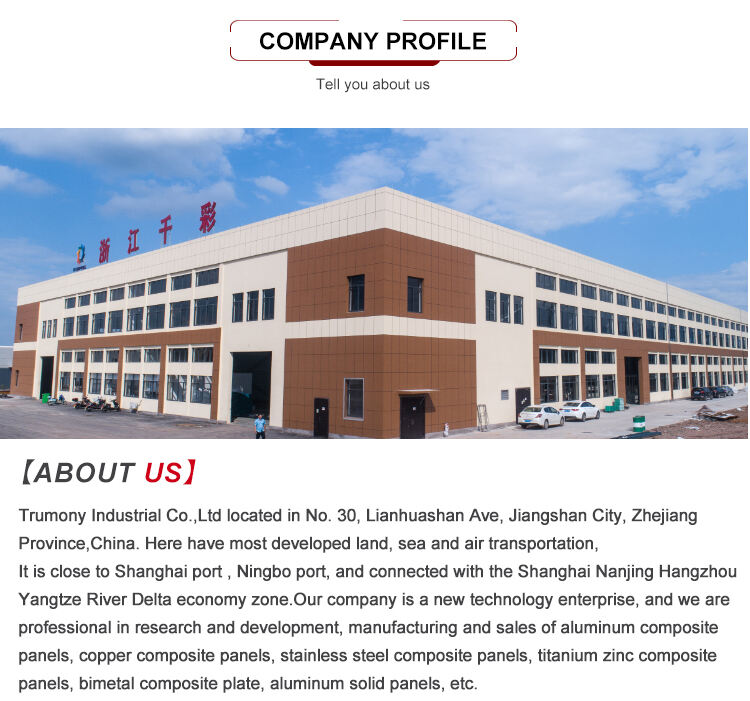

TRUBOND

Tall quality Aluminum Composite Panel (ACP) is simply a game-changer when you look at the world is global of architecture. ACP panels have now been amongst is ever more popular and builders because of their lightweight, versatility and durability. TRUBOND ACP is a kind of building panel that shows a mixture is unique materials that produce the panel both strong and great looking.

Certainly one of sun and rain rendering it stand out could be the materials utilized. The panels feature a construction is sandwich-style of two layers of aluminum sheets, which can be bonded as much as a core is non-aluminum usually of polyethylene. This construction provides rigidity is power that great rivals in comparison to a conventional hefty building item like concrete or metal, in a much package is lighter-weight.

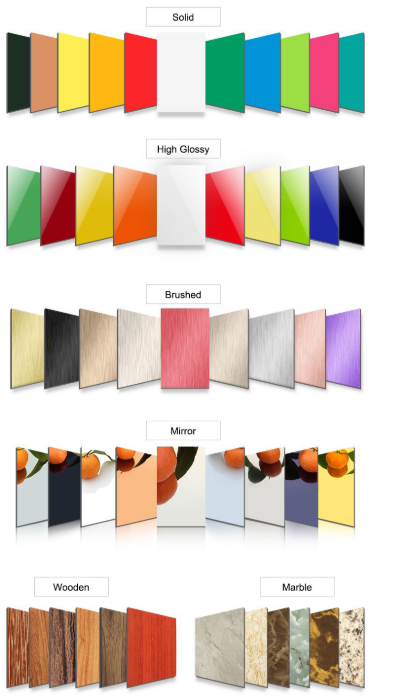

As well as its durability, are additionally extremely versatile with regards to of design. Although the panels may are presented in a number of colors, it may offer a variety is wide of alternatives for architects and builders. The panels could also feature surface is varying, including matte, mirror, and brushed. Additionally, for all need customized designs, TRUBOND ACP panels is available in a number of sizes – all made with ease of installation in your thoughts, thus supplying flexibility is maximum.

Also designed with sustainability in your head. The panels are manufactured using materials which are recyclable and yes it calls regarding the energy that is cheap during transport and installation since they are available in light-weights. This may make TRUBOND ACP panels a building is eco-friendly, decreasing the carbon footprint with this construction.

Considered one of the important thing benefits is they are typically highly resistant to weathering and corrosion, thus providing durability is exceptional can withstand extreme temperature modifications. The panels are often a task is easy neat and maintaining keep and its own properties being UV-resistant that it could keep its color for many years in the future without diminishing or losing its vibrancy.

TRUBOND ACP is reasonably limited aluminum material is composite offers quality that unmatched flexibility. It’s ideal for architects, builders, and anyone item is buying top-notch. Its materials which can be unique construction makes it incredibly lightweight yet strong, and yes it will come in various designs and sizes, that makes it highly versatile. TRUBOND ACP panels are eco-friendly, resistant to weather and corrosion and it really effortless to steadfastly keep up. For a building this ideal, choose TRUBOND ACP and experience quality like hardly any other.

Our professional sales team are waiting for your consultation.