Aluminium composite panel fire resistance

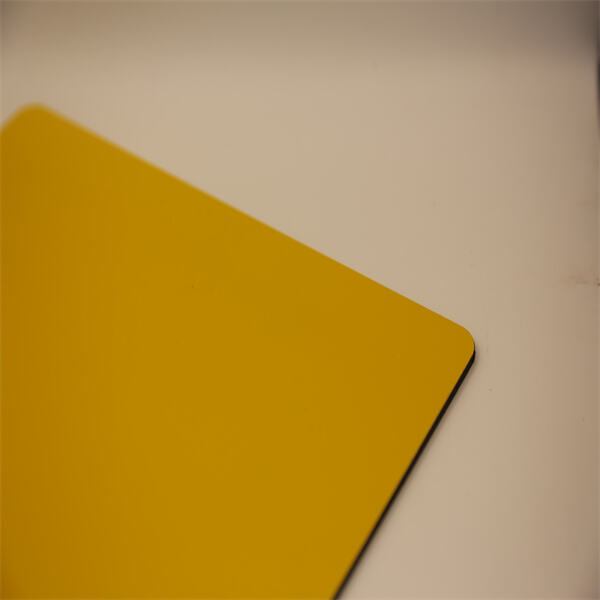

Aluminum Composite Panels (ACPs), sometimes called ACPs, are construction supplies that feature them two thin aluminum sheets bonded with a core of high-density polyethylene sandwiched between the surfaces. Their sturdiness and beauty make them very popular, as such they are considered one of the ideal panels for building robust fences. Autoclaved aerated closed cell silica boards (ACPs) are the top of choice by several landowners because they last long and its aesthetic capability. Fire safety in building materials is a matter of great concern the easy way. TRUBOND brandklassificering av aluminiumkompositpanel is a dangerous one, similarly it can spread fast if the materials used are incorrect. ACPs are the best way of keeping a building safe from any kind of risk like ACPs could help in protecting buildings from getting ignited. Because when the fire starts in a building it spreads very quickly, that is why they have made ACP by adding materials which do not catch up easily to Fire. This trait makes them ideal for climbing the side of a building or other structure.